High Wear Resistant Secondary Conveyor Belt Cleaner Heavy Duty Cleaner Scraper for Coal Mining

Basic Info

| Model NO. | DB-PPU/DB-ZPPU |

| Condition | New |

| Type of Belt Cleaner | Secondary |

| Spring Tensioner | Stainless Steel |

| Certification | ISO9001:2008 & SGS |

| Position of Installation | Conveyor Head Pulley, 100mm From Head Pulley |

| Advantage | Manufacturer with Extensive Experience |

| Product Name | Mining Heated Conveyor Belt Cleaner PU Scraper |

| Transport Package | Plywood Case |

| Specification | 650-2200 |

| Trademark | Debon |

| Origin | Jiaozuo, Henan, China |

| HS Code | 8431390000 |

| Production Capacity | 500 Pieces/Week |

Product Description

high wear resistant Secondary conveyor belt cleaner Heavy duty cleaner scraper for Coal mining All the types of belt cleaner

The secondary Polyurthane belt cleaner:Description:

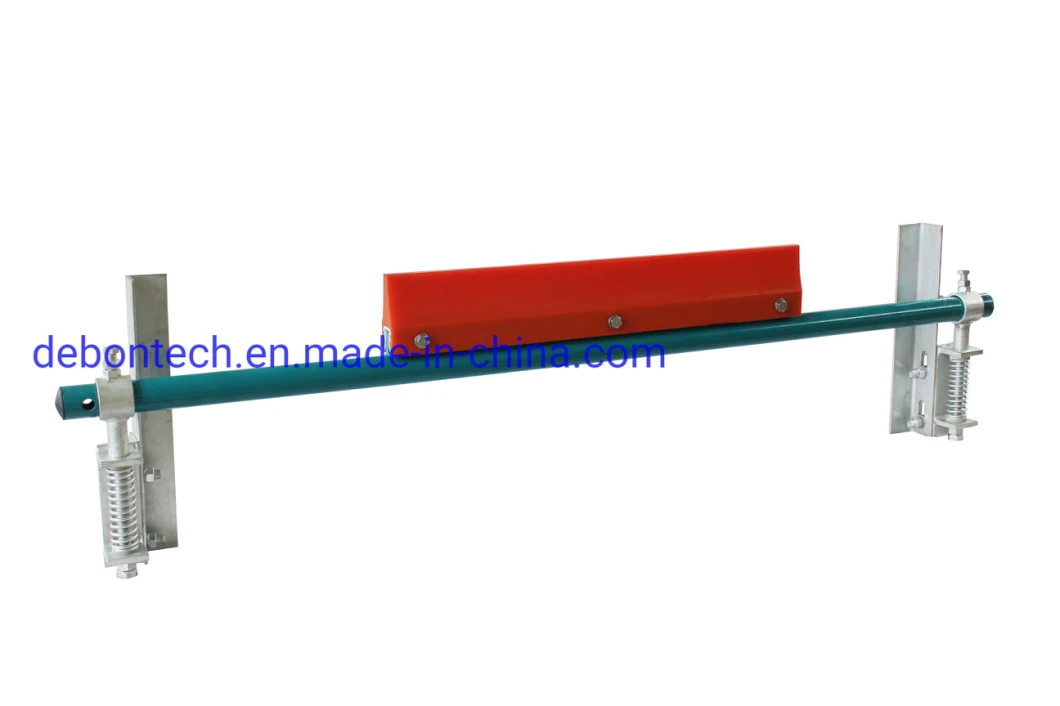

DB-PPU Secondary Polyurethane Belt Cleaner can be mounted in any secondary cleaning position---usually about 100mm from where the belt leaves the head pulley.

The secondary cleaner, used together with the primary cleaner, has a self-adjusting spring tensioner system to maintain close contact with the belt without damaging the belt and achieve good cleaning results.

4.Material Humidity: ≤15%

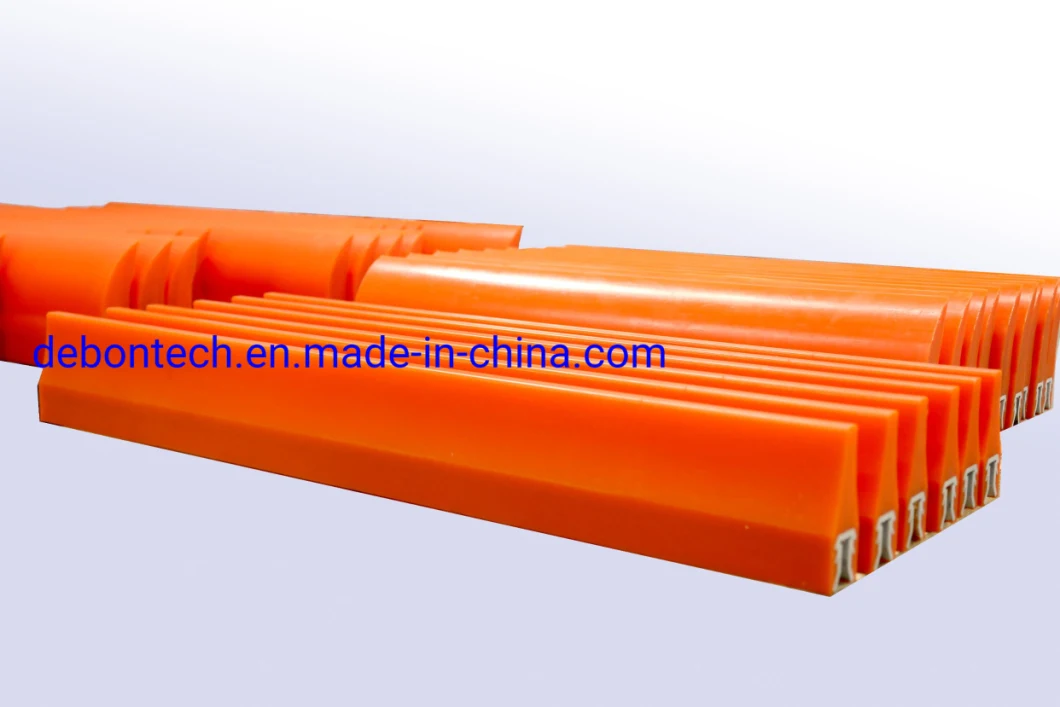

DB-ZPPU heavy duty polyurethane belt cleaner ,which is increased the size of the PU blade and prolongs service-time of the cleaner, is suitable for the high speed conveyor system.

Applications:

1.Belt Width: 450~2400mm2. Belt Speed: >3.5(m/s)3.Temperature:-40~90ºC4.Material Humidity: ≤ 15%

DB-PPA secondary polyurethane with alloy scraper belt cleaner is installed at the flat working face of the return conveyor belt at the lower part of the head roller. The structure of the scraper is designed with multi-level buffering (1. Polyurethane with a Tungsten Carbide Tip 2. rubber torsion pad, 3. spring system). The multi-level buffering works together to alleviate the impact force when colliding with the buckle, and make the scraper tungsten carbide tip leave quickly when passing through the buckle, so that it can pass easily without damaging the conveyor belt. This type cleaner is suitable for poor working environmental.Applications:

1.Belt Width:450~2400(mm)

2.Suitable for both mechanical or vulcanized joint belt.

3.Suitable for tough applications with wet,sticky carry-back.

4. Unique spring tension.

Features:

1) Excellent Wear Resistance2) High Temperature Resistant3) Great cleaning effect4) No damaging the belt

Specification:

Company:

Jiaozuo Debon Technology is a factory dedicated to the production, development and application of wear liners for mining facilities since 2001. The company has advanced production lines and testing apparatuses for rubber, polyurethane and ceramic and can provide wear solutions for various requirements for wear protection by using different wear-resistant materials.Main products include:pulley lagging, impact bed, conveyor belt cleaner, conveyor skirting, ceramic rubber composite liner, conveyor belt repairmaterials, etc. We could develop and produce different wear-resistant products according to customer requirements.Our products are widely exported to the UK, France, the United States, Australia, Russia, Kazakhstan, Southeast Asia and other countries and regions, and we also have large market shares and good reputations in China. Over the years, we have been winning good feedback from customers with high quality and consistency.

Certification:

Our Exhibition:Related Products:

Further information, welcome to contact Mrs.Mona Chueng.